In industries such as food processing, pharmaceuticals, cosmetics, chemicals, and adhesives, mixing plays a pivotal role in product consistency, quality, and performance. When dealing with high-viscosity materials, complex formulations, or heat-sensitive products, one solution stands out: the multi-shaft mixer.

This advanced mixing technology offers versatility, precision, and control for even the most challenging applications. In this ultimate guide, we’ll explore the functions, types, and key advantages of multi-shaft mixers — and why forward-thinking manufacturers around the world are turning to companies like Orisun, a leader in mechanical design and manufacturing, to deliver reliable, custom-engineered mixing solutions.

What Is a Multi-Shaft Mixer?

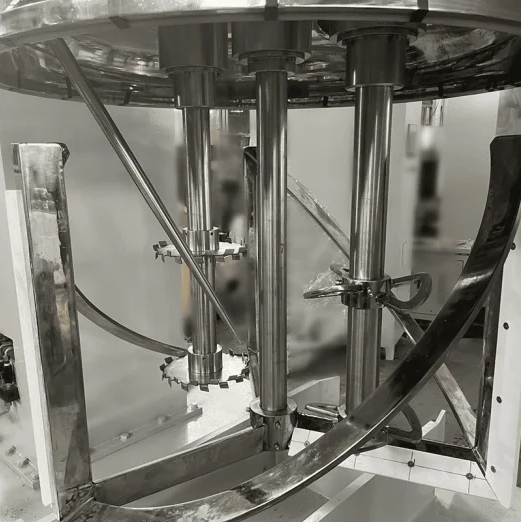

A multi-shaft mixer is an industrial mixing system that incorporates two or more mixing shafts, each operating at different speeds and often with different types of agitation. This combination provides enhanced shear, superior heat transfer, and improved product homogeneity — particularly when dealing with high-viscosity or multi-phase materials.

Multi-shaft mixers are commonly used for:

Emulsifying and homogenizing creams, gels, and pastes

Dispersing powders into liquids

Heating and cooling during mixing

Vacuum mixing or deaeration

Their modularity and customization make them ideal for batch processing in medium to large-scale production.

Core Functions of a Multi-Shaft Mixer

1. Simultaneous Mixing and Shearing

One shaft (often a high-speed disperser) handles intense shearing and particle breakdown, while a second (or third) shaft performs slow, powerful mixing to maintain uniformity.

2. Temperature Control

Many systems integrate jacketed mixing vessels for efficient heating or cooling, allowing for precise thermal regulation during processing.

3. Deaeration

Vacuum capabilities eliminate trapped air, which is crucial in products like pharmaceuticals, cosmetics, and high-performance adhesives.

4. Flexibility for Various Viscosities

Multi-shaft mixers handle a wide range of viscosities, from low-viscosity liquids to heavy pastes and semi-solids — even in the same system.

Common Types of Multi-Shaft Mixers

1. Dual-Shaft Mixer

One high-speed disperser + one low-speed anchor

Ideal for mixing medium- to high-viscosity materials

Used in adhesives, sealants, and coatings industries

2. Triple-Shaft Mixer

Typically includes:

A high-speed disperser

A slow-speed anchor agitator

A rotor-stator homogenizer

Offers unmatched versatility for complex emulsions and thermal-sensitive products

3. Custom Multi-Shaft Systems

Designed for specific process requirements, including inline feeding, vacuum operation, CIP (Clean-in-Place), and automated controls

Often used in regulated industries like biotech or pharma

Advantages of Multi-Shaft Mixers

1. Enhanced Mixing Efficiency

By combining different mixing actions, these systems drastically reduce processing times and ensure even distribution of ingredients.

2. Versatility

Multi-shaft mixers accommodate a wide range of formulas, viscosities, and batch sizes, making them a go-to solution across industries.

3. Scalability

From pilot-scale systems to full production units, these mixers scale seamlessly while maintaining product consistency.

4. Gentle Yet Powerful

The presence of a slow-speed agitator ensures thorough blending without damaging delicate ingredients, while high-speed dispersers handle more robust tasks.

5. Superior Heat Transfer

The anchor agitator constantly scrapes the tank walls, enhancing heat exchange and minimizing hot or cold spots.

Orisun: Engineering Excellence in Mixing Technology

As a company dedicated to mechanical design and manufacturing, Orisun has earned a reputation for delivering precision-engineered, high-performance multi-shaft mixing systems tailored to client-specific applications.

Why Choose Orisun?

Custom Engineering: Orisun collaborates closely with customers to understand process requirements, fluid dynamics, and end-product specifications.

Quality Manufacturing: Built using high-grade stainless steel and advanced machining processes, Orisun mixers are designed for durability and cleanability.

Innovation-Driven Design: Every system incorporates the latest in automation, safety controls, and energy efficiency.

Technical Expertise: Orisun provides end-to-end support, from concept and 3D modeling to installation, commissioning, and after-sales service.

Whether you need a simple dual-shaft setup or a fully integrated mixing station with PLC controls, Orisun can develop a reliable, efficient, and future-ready solution.

Applications Across Industries

Multi-shaft mixers from Orisun are already in use in a wide variety of industries:

Cosmetics – Creams, lotions, serums, pastes

Pharmaceuticals – Ointments, suspensions, controlled-release gels

Food – Sauces, flavor emulsions, high-viscosity syrups

Adhesives & Sealants – High-performance bonding pastes

Chemical Processing – Polymers, resins, lubricants

Conclusion

In competitive manufacturing landscape, achieving consistent product quality while maximizing process efficiency is non-negotiable. Multi-shaft mixers provide the flexibility, control, and performance that modern production demands — and when designed by an experienced engineering partner like Orisun, they become a strategic investment in operational success.

Whether you’re launching a new product line or optimizing an existing process, trust Orisun to deliver the mixing solutions that keep your production smooth, scalable, and future-ready.

Optimizing Mixing Performance: Tips for Operating Multi-Shaft Mixers

www.orisunmachinery.com

Orisun