Industrial plants, whether in petrochemical, power generation, steel production, shipbuilding, or ocean engineering, operate in complex and often hazardous environments. Ensuring the safety of personnel, equipment, and the environment is paramount. One of the most effective methods to enhance operational safety in these settings is through the strategic use of mechanical valve interlocks. These devices enforce correct operational sequences, prevent human error, and integrate seamlessly into broader safety systems.

Nudango, a leading provider of industrial safety solutions, has established itself as a trusted partner in designing and implementing safety systems. With CE, HSE, and other system certifications, Nudango provides domestic and international clients with high-quality valve interlocks, trapped key interlocking systems, remote and portable valve actuators, and valve position indicators. These products have been widely adopted across multiple industries, demonstrating their effectiveness in ensuring operational safety.

The Importance of Mechanical Valve Interlocks in Industrial Plants

Mechanical valve interlocks are physical devices designed to control the operation of valves by enforcing strict operational sequences. Unlike electronic or software-based interlocks, mechanical systems provide a fail-safe mechanism that physically prevents unsafe actions. Their importance in industrial plant design lies in their ability to:

-

Prevent Human Error: Human mistakes are a leading cause of industrial accidents. Mechanical interlocks prevent operators from opening or closing valves in the wrong order, reducing the likelihood of dangerous incidents.

-

Ensure Regulatory Compliance: Industrial plants must adhere to strict safety regulations. Mechanical interlocks help ensure operations comply with international standards, including CE, HSE, and ISO certifications.

-

Enhance Process Reliability: By enforcing proper valve sequences, mechanical interlocks contribute to the consistent and reliable operation of complex processes.

Nudango’s products, including trapped key interlocking systems and valve position indicators, provide industrial plants with robust solutions to implement these safety measures effectively.

Key Considerations for Designing Safe Plants

Designing a safe industrial plant involves integrating mechanical valve interlocks into a comprehensive safety strategy. Several considerations are critical in this process:

-

Process Mapping and Risk Analysis

The first step in designing a safe plant is understanding the processes and identifying potential hazards. Engineers must map the flow of materials, energy, and information, and pinpoint where unsafe valve operations could lead to accidents. This risk analysis informs the placement and configuration of mechanical valve interlocks to ensure that critical sequences are always enforced. -

Selection of Appropriate Interlocks

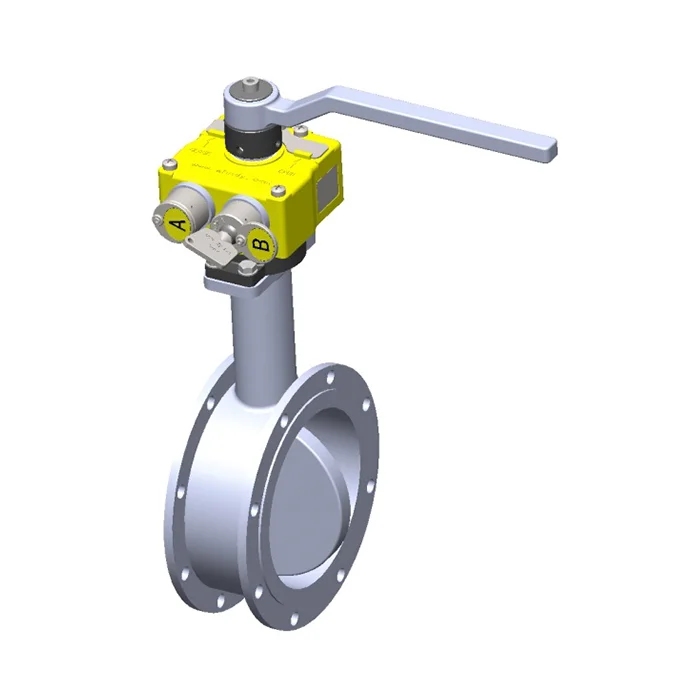

Different industrial processes require different types of interlocks. Common mechanical valve interlocks include:Nudango’s diverse product portfolio allows engineers to select the right combination of interlocks tailored to the specific requirements of their plant.

-

Trapped Key Interlocks: Ensure that valves are operated in a predetermined sequence using physical keys.

-

Remote Valve Actuators: Allow operators to control valves from a safe distance, reducing exposure to hazardous environments.

-

Portable Valve Actuators: Offer flexibility for maintenance operations or emergency interventions.

-

Valve Position Indicators: Provide visual confirmation of valve status, enabling operators to verify the system’s state at a glance.

Integration with Existing Safety Systems

Industrial plants often use SCADA systems, programmable logic controllers (PLCs), and other monitoring tools to manage operations. Mechanical valve interlocks should integrate seamlessly with these systems, allowing operators to monitor valve status in real-time and coordinate with automated processes. This integration enhances both safety and operational efficiency.

Material and Environmental Considerations

Industrial plants often operate under extreme conditions, including high pressure, high temperature, or corrosive environments. Selecting interlocks made from durable, corrosion-resistant materials is essential to ensure long-term reliability. Nudango’s products are designed to withstand such conditions, providing consistent performance in demanding industrial settings.

Ease of Operation and Maintenance

While safety is critical, interlocks must also be user-friendly. Operators should be able to manipulate valves efficiently, and maintenance personnel should have straightforward access for inspection and servicing. Portable and remote actuators, combined with clear valve position indicators, streamline operations while maintaining safety standards.

Redundancy and Fail-Safe Design

In critical processes, failure is not an option. Mechanical interlocks should incorporate fail-safe designs to prevent unsafe operations even if a component fails. Trapped key systems inherently provide redundancy, as physical keys cannot be bypassed, ensuring proper operational sequences are maintained under all circumstances.

Training and Standard Operating Procedures

A well-designed interlock system is only effective if personnel understand how to use it correctly. Comprehensive training programs and standard operating procedures (SOPs) are essential for ensuring operators and maintenance teams can safely and effectively interact with interlocks. Nudango provides technical guidance and support to facilitate proper training and implementation.

Advantages of Implementing Mechanical Valve Interlocks

Integrating mechanical valve interlocks into an industrial plant design offers several advantages:

-

Enhanced Safety: Prevents incorrect valve operations that could lead to accidents, equipment damage, or environmental hazards.

-

Operational Consistency: Ensures processes run smoothly by enforcing correct sequences of valve operations.

-

Regulatory Compliance: Helps plants meet international safety standards and avoid penalties.

-

Reduced Human Error: Provides a physical barrier against mistakes that can compromise plant safety.

-

Durability and Reliability: High-quality materials and fail-safe designs ensure long-term performance even in challenging environments.

Case Studies: Industrial Applications

Nudango’s mechanical valve interlocks have been successfully implemented in a wide range of industries:

-

Petrochemical Plants: Complex chemical processes require precise valve sequencing to prevent leaks, mixing errors, and overpressure incidents. Trapped key interlocks and remote actuators enhance both safety and efficiency.

-

Power Generation Facilities: High-voltage operations demand strict control over valve movements. Mechanical interlocks prevent inadvertent actions that could disrupt operations or endanger personnel.

-

Steel Manufacturing: Operations involving molten metal and high-temperature processes benefit from robust interlock systems that maintain integrity under extreme conditions.

-

Shipbuilding and Ocean Engineering: Offshore platforms and vessels operate in dynamic environments. Remote and portable actuators combined with mechanical interlocks ensure safe valve operations even in challenging maritime conditions.

Future Trends in Mechanical Valve Interlocks

Looking ahead, mechanical valve interlocks are evolving to meet the needs of increasingly complex industrial environments. Key trends include:

-

Integration with Digital Monitoring Systems: Combining mechanical interlocks with sensors for real-time monitoring and predictive maintenance.

-

Enhanced Automation: Supporting remote and automated valve operation for improved safety and efficiency.

-

Material Innovation: Developing more durable, lightweight, and corrosion-resistant interlocks suitable for extreme environments.

-

Customization: Tailoring interlocks for specific industry requirements, ensuring compliance with local and international standards.

Nudango is at the forefront of these trends, providing innovative solutions that combine traditional mechanical reliability with modern technological enhancements.

Conclusion

Designing a safe industrial plant requires a comprehensive approach to risk management, operational control, and regulatory compliance. Mechanical valve interlocks play a crucial role in this process by physically enforcing correct valve operation sequences, preventing human error, and integrating with broader safety and automation systems.

By leveraging high-quality interlocks from experienced providers like Nudango, industrial plants can achieve enhanced safety, operational reliability, and regulatory compliance. With a product portfolio that includes trapped key systems, remote and portable actuators, and valve position indicators, Nudango demonstrates how mechanical valve interlocks can be effectively applied across diverse industrial settings, from petrochemical plants to offshore platforms.

Investing in mechanical valve interlocks is not just about compliance—it is a strategic decision to protect personnel, safeguard equipment, and ensure the long-term success of industrial operations.

www.nudango.com

nudango