https://www.cable-sf.com/Custom-New-Energy-Harness.html

Our factory enjoys a distinct edge in customizing high-voltage wiring harnesses for new energy vehicles. Boasting a senior professional team, advanced manufacturing techniques, a rigorous quality control system, and a high-level commitment to environmental protection and safety, we can offer highly individualized solutions to ensure that products not only precisely align with customer demands but also conform to international certification standards. To bring efficient, safe and reliable wiring harness products to customers.

The use of high-quality insulation materials, high temperature resistance, corrosion resistance, to ensure stable operation in extreme environments and pure copper wire is selected to reduce energy loss and improve power transmission efficiency.

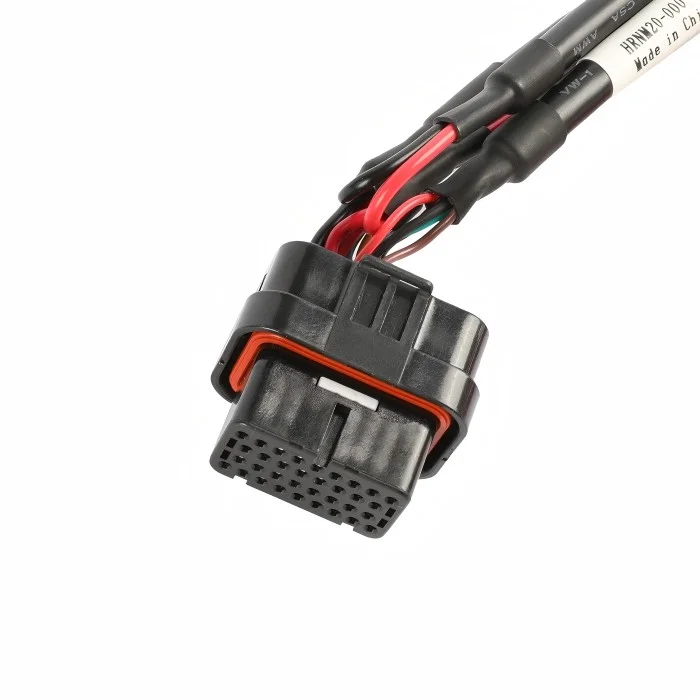

Equipped with various connectors, compatible with a variety of new energy models and According to customer needs, provide one to one customized all kinds of wiring harness products and services.

Custom New Energy Harness

As a trusted new energy wiring harness supplier, we present our custom new energy harness solution designed for electric vehicles, energy storage systems, charging stations, and related new energy equipment. This wiring harness system supports both high-voltage power transmission and low-voltage control/signal lines, offering a one-stop, fully tailored solution to meet diverse project requirements.

New Energy Wiring Harness Key Features & Benefits

High Voltage & Safety Design

Utilizes high-grade insulation materials (e.g. XLPE, TPE, fluoropolymer) to withstand elevated temperatures and voltage stress

Meets or exceeds required dielectric strength with robust insulation thickness and rigorous voltage-withstand testing

Incorporates creepage/clearance design, shielding, and grounding paths to ensure electromagnetic compatibility (EMC) and system safety

Tailored Customization

Fully custom wiring layout based on your schematics: wire lengths, branch points, connectors, wire gauges, shielding, bundle structure, color coding, labeling

Wide compatibility with mainstream connector types (e.g. Deutsch, TE, Amphenol, IP-rated, waterproof plugs)

Support for variant versions (e.g. different lengths, branch count, power ratings) with repeatability

Quality Assurance & Testing

Every harness is 100% tested with continuity, insulation resistance, and dielectric / high-voltage (hipot) tests

Optional environmental reliability tests (thermal cycling, vibration, salt spray, humidity) per customer requirements

Full traceability on wire batches, components, production logs

Regulatory & Material Compliance

Non-toxic materials for safe operation

Design for Manufacturability & Serviceability

Modular segments and service loops for easy maintenance or replacement

Clear and permanent labeling of each branch and end for installation convenience

Strain relief, protective sleeves, tubing, clamps to protect wires from abrasion and stress

Typical Applications

Main wiring harness and sub-harnesses for electric vehicles

Battery pack interconnect harnesses (BMS to modules)

High-voltage to motor / inverter / charger harnesses

Energy storage system wiring between modules, racks, converters

Charging station internal harnesses

Photovoltaic / solar power system wiring bundles

Various control, sensor, and communication wiring in new energy equipment

Because we specialize in new energy wiring harness development, we understand the challenges in durability, safety, and system integration in these environments.

Customization & Ordering Process

Requirement Submission

Send us your wiring diagram, connector types, wire gauges, branch layout, environment constraints, quantity, and any special test requirements.

Design Proposal & Quotation

Our engineering team reviews and optimizes wiring layout, calculates voltage drop, suggests materials, then issues a formal drawing and quote.

Sample Fabrication & Validation

We build sample harness(es) for your testing — electrical performance, fit & form check, environmental tests.

Mass Production

On sample approval, we proceed to volume production under controlled quality processes.

Final Testing & Delivery

Each batch undergoes full QC testing, labeling, packaging, and shipment. We also offer post-delivery technical support.

Why Choose Us

Focused expertise as a new energy wiring harness supplier

Strong R&D capability and experience in high-voltage / hybrid / battery interconnect systems

Rigorous quality management and component traceability

Flexible customization from prototype to high-volume

On-time delivery, global logistics support, and responsive after-sales service

Packaging & Shipping

Individual harnesses are packaged with protective wrapping, labels, anti-static and moisture-proof bags

Bundles secured to avoid damage during transit

Shipping options: air freight, sea freight, express courier — arranged per your location and urgency

FAQ

Q: How do you ensure harness reliability?

A: We test every harness electrically, optionally run environmental stress tests, and maintain strict manufacturing controls.

https://www.cable-sf.com/Custom-New-Energy-Harness.html

Dongguan Shuofeng Electronics Co., Ltd.