In today’s highly competitive beverage market, bottling efficiency is no longer a “nice to have” — it is a core factor that directly affects production costs, product consistency, and delivery speed. As water and beverage brands scale up to meet growing demand, manual or semi-automatic filling methods often become bottlenecks. This is where automatic water filling machines play a decisive role.

Automatic water filling machines integrate filling, capping, conveying, and control into a single, streamlined process. They are designed to reduce labor dependency, minimize product loss, and ensure consistent quality across large production volumes. This article explores how these systems improve bottling efficiency in real-world operations and why they have become essential equipment for modern bottling plants.

The Bottling Efficiency Challenge in Modern Plants

Water bottling may appear straightforward, but in practice it involves multiple tightly linked steps: water treatment, bottle forming, rinsing, filling, capping, labeling, and secondary packaging. Inefficiencies in any one step can slow the entire line.

Common challenges faced by traditional bottling operations include:

-

Inconsistent fill levels due to manual control

-

High labor intensity and rising labor costs

-

Frequent downtime caused by human error

-

Hygiene risks from excessive manual handling

-

Difficulty scaling production during peak demand

Automatic water filling machines are designed specifically to address these issues at both technical and operational levels.

How Automatic Water Filling Machines Work

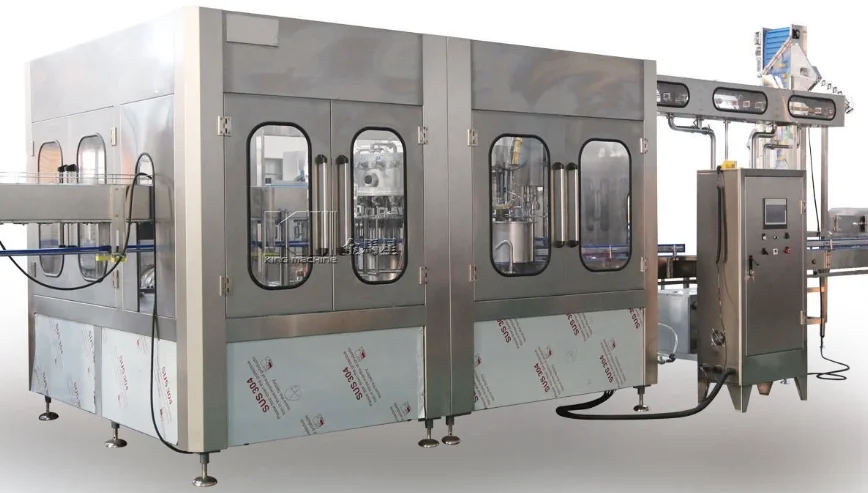

An automatic water filling machine uses precision-controlled valves, sensors, and programmable logic controllers (PLCs) to manage the entire filling process. Bottles are conveyed into the filling zone, aligned precisely, filled to a preset level, capped automatically, and transferred to the next stage without manual intervention.

Modern systems often integrate seamlessly with upstream and downstream equipment such as water treatment systems, PET blow molding machines, labeling machines, and packaging lines. This integration transforms separate machines into a continuous production flow.

Key Ways Automatic Water Filling Machines Improve Efficiency

1. Higher Throughput with Stable Output

One of the most direct benefits is increased production speed. Automatic water filling machines can process thousands of bottles per hour while maintaining stable output. Unlike manual filling, speed does not fluctuate due to operator fatigue or inconsistency.

Because filling volume, timing, and capping torque are controlled electronically, the system maintains the same performance level over long production runs. This stability allows manufacturers to plan output accurately and meet delivery schedules with confidence.

2. Consistent Fill Accuracy and Reduced Waste

Overfilling and underfilling are common problems in manual or semi-automatic systems. Overfilling increases product loss, while underfilling risks regulatory non-compliance and customer complaints.

Automatic water filling machines use flow meters, level sensors, or gravity-controlled filling valves to ensure each bottle receives the correct amount of water. This precision reduces raw material waste and ensures uniform product presentation across batches.

Over time, the reduction in water loss alone can lead to measurable cost savings, especially in high-volume operations.

3. Lower Labor Dependency and Better Workforce Allocation

Automation significantly reduces the need for manual intervention in the filling process. Instead of multiple operators managing filling and capping, a single technician can oversee the system, monitor performance, and respond to alerts.

This does not eliminate the workforce but allows companies to redeploy skilled employees to higher-value tasks such as quality control, maintenance, or production planning. In regions where labor availability is limited or costs are rising, this shift can be critical for long-term sustainability.

4. Improved Hygiene and Product Safety

Hygiene is a top priority in bottled water production. Automatic water filling machines are designed with food-grade materials, enclosed filling zones, and clean-in-place (CIP) systems that reduce the risk of contamination.

By minimizing human contact with bottles and water during filling and capping, these systems help maintain strict hygiene standards. This is particularly important for export-oriented producers who must comply with international quality and safety regulations.

5. Faster Changeovers and Flexible Production

Modern bottling plants often produce multiple bottle sizes or packaging formats. Automatic water filling machines are designed for fast changeovers through adjustable components and programmable settings.

Instead of lengthy mechanical adjustments, operators can switch between bottle formats by selecting predefined parameters on the control interface. This flexibility reduces downtime and makes small-batch or multi-product production more efficient.

Integration with Smart Factory Concepts

Efficiency gains are further amplified when automatic water filling machines are deployed as part of an intelligent production system.

Companies like Pengxiang Huixing focus on intelligent workshop and smart factory planning, where filling machines are connected with upstream water treatment systems and downstream packaging, warehousing, and logistics processes. Data collected from sensors and control systems can be used to:

-

Monitor real-time production performance

-

Predict maintenance needs

-

Optimize energy and water usage

-

Improve traceability and quality control

This level of integration transforms filling equipment from standalone machines into data-driven production assets.

Real-World Applications Across Global Markets

Automatic water filling machines are widely used in bottled water, mineral water, purified water, and functional beverage production. Their adaptability makes them suitable for both small local brands and large-scale export-oriented manufacturers.

Pengxiang Huixing, based in Shenzhen, China, has over 20 years of experience in beverage packaging machinery. The company provides complete solutions covering water treatment, PET blowing, filling and capping, labeling, conveying, and secondary packaging. Its automatic filling systems are deployed not only across more than 20 provinces in China but also in international markets such as the UAE, Oman, Vietnam, the Philippines, and Malaysia.

This global adoption reflects the practical value of automation in improving bottling efficiency under diverse operating conditions.

Choosing the Right Automatic Water Filling Machine

Efficiency improvements depend on selecting equipment that matches actual production needs. Key factors to consider include:

-

Target output capacity per hour

-

Bottle type and size range

-

Integration with existing production lines

-

Cleaning and maintenance requirements

-

Long-term technical support and service

For manufacturers seeking reliable, production-ready solutions, detailed technical information about modern systems can be found at

<a href="https://www.szpxhx.com/Water-filling-machine">automatic water filling machine</a>.

Long-Term Impact on Competitiveness

Beyond immediate efficiency gains, automatic water filling machines contribute to long-term competitiveness. They support consistent product quality, enable faster market response, and create a scalable production foundation.

As consumer demand grows and regulatory requirements become stricter, manual processes struggle to keep pace. Automation provides the control, reliability, and transparency needed to operate efficiently in both domestic and international markets.

Conclusion

Automatic water filling machines are no longer optional equipment for serious bottling operations. They address fundamental efficiency challenges by increasing throughput, improving accuracy, enhancing hygiene, and reducing reliance on manual labor.

When combined with intelligent factory planning and integrated production lines, these machines become central to modern beverage manufacturing strategies. For water producers aiming to improve efficiency without compromising quality, automation is a practical and proven path forward.

www.szpxhx.com

Pengxiang Huixing