In the last decade, advances in robotics, unmanned aerial vehicles (UAVs), industrial automation, and intelligent navigation systems have made inertial sensing technology more crucial than ever. At the core of these technologies lies a compact yet powerful sensing component—the six-axis MEMS Inertial Measurement Unit (IMU). With tri-axial gyroscopes and tri-axial accelerometers integrated into a miniature package, six-axis IMUs enable precise measurement of acceleration, angular rate, position, and orientation. This allows machines—land, air, underwater, or even wearable—to sense motion, execute autonomous control, and react intelligently to environmental dynamics.

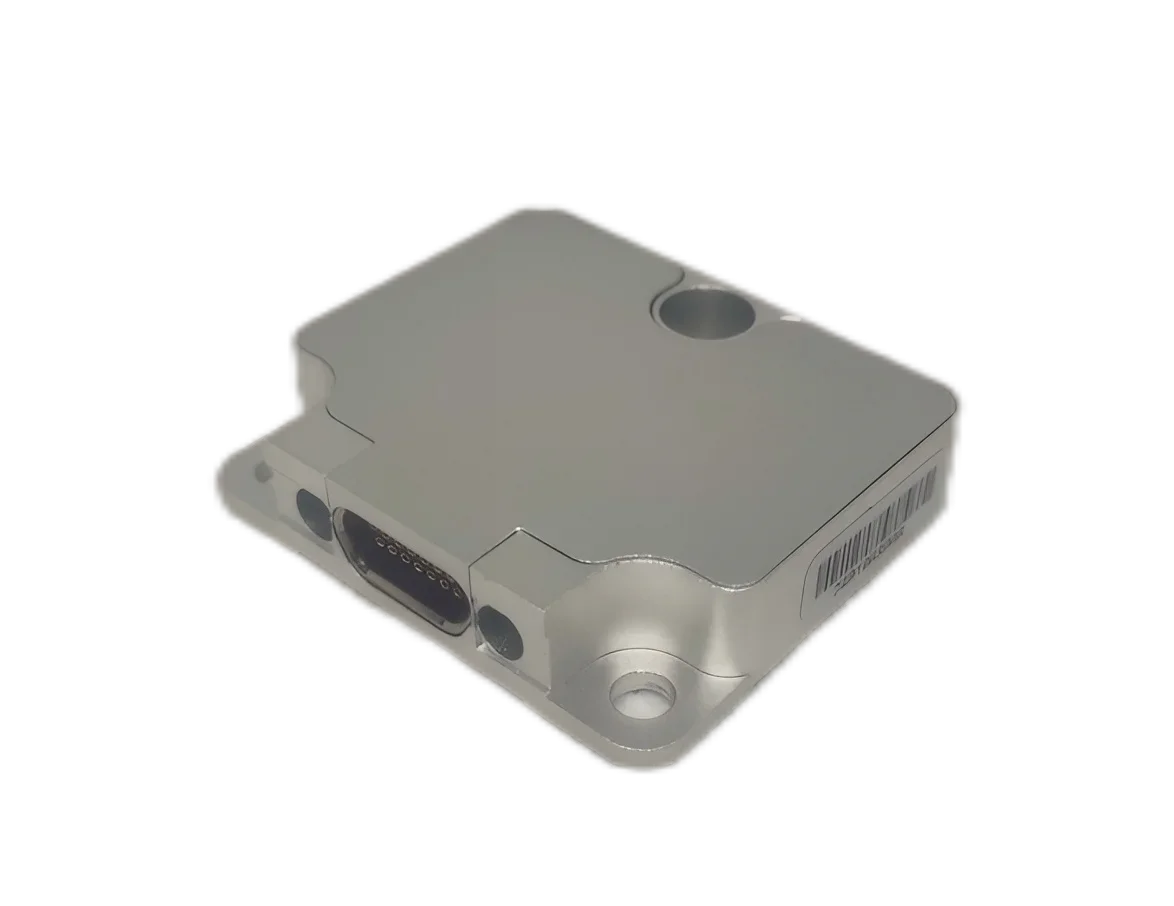

A leader in this field, LINS, is a high-tech enterprise dedicated to inertial sensing technology research and development, testing, and full-stack product integration. LINS specializes in designing miniaturized, high-precision, industrial-grade MEMS IMUs characterized by low noise density, high dynamic range, drift compensation, shock resistance, temperature stability, and long-term reliability, making them suitable for demanding robotics and UAV applications.

This comprehensive article explores in depth:

-

the fundamentals of six-axis MEMS IMUs

-

their architecture and performance attributes

-

top applications in robotics and drones

-

emerging markets and case studies

-

integration challenges and solutions

-

typical requirements in industrial and defense applications

-

LINS product advantages

-

future trends, FAQs, and more

By the end, you will understand how six-axis MEMS IMUs underpin the future of autonomy and intelligent machine perception.

1. What is a Six-Axis MEMS IMU?

A six-axis MEMS IMU integrates:

-

3-axis gyroscope → angular velocity

-

3-axis accelerometer → linear acceleration

These two sensing systems—placed orthogonally—generate real-time motion data with:

-

high sampling rate

-

high bandwidth

-

fast response time

Six-axis IMUs are widely used because they offer:

| Feature | Benefit |

|---|---|

| Compact Size | Suitable for mobile & miniaturized systems |

| Low Power | Ideal for battery-powered platforms |

| Rugged Design | Works under shock/vibration |

| High Reliability | Long operating lifespan |

| Digital Interfaces | Easy integration |

LINS enhances these advantages via:

-

multi-stage factory calibration

-

temperature drift correction

-

advanced digital filtering

-

bias compensation algorithms

Together, these innovations provide industrial-grade inertial sensing performance.

2. Core Working Principles of MEMS IMUs

To appreciate the full value of IMUs, it helps to understand how they work.

2.1 Gyroscopes

Gyros measure rotational velocity using:

-

Coriolis effect sensing

-

vibrating structure MEMS

-

integrated capacitive pick-off detection

Their precision affects:

-

attitude estimation error

-

drift characteristics

-

gyroscopic bias stability

2.2 Accelerometers

Accelerometers detect linear motion and gravity vectors via:

-

proof mass displacement

-

capacitive sensing

-

differential measurement

They support:

-

dead-reckoning

-

gravity compensation

-

motion tracking

2.3 Sensor Fusion

IMU output is commonly fused with:

-

magnetometers

-

GNSS receivers

-

cameras

-

LiDAR

using algorithms like:

-

Kalman filters

-

Complementary filters

-

SLAM algorithms

-

INS/GNSS fusion

This improves robustness and reduces drift.

LINS IMUs incorporate built-in calibration that enables more accurate heading, position, and velocity estimation.

3. Top Applications in Robotics

3.1 Autonomous Mobile Robots (AMRs)

Modern AMRs rely on IMUs for:

-

dead reckoning when wheels slip

-

motion prediction for SLAM

-

heading estimation during GNSS loss

-

dynamic path correction

Use cases include:

-

logistics and warehousing

-

factory automation

-

hospital delivery robots

-

last-mile distribution

For example:

A warehouse AMR typically integrates:

-

LiDAR → environment mapping

-

wheel encoders → odometry

-

IMU → drift correction & stability

When encoders fail due to:

-

uneven flooring

-

wheel slip

-

dust or moisture

IMUs ensure reliable navigation.

A LINS IMU with low drift and strong vibration resistance dramatically enhances navigation accuracy.

3.2 Industrial Robotic Arms

Six-axis IMUs assist in tasks requiring:

-

dynamic control

-

precision positioning

-

trajectory optimization

-

tool stabilization

Applications include:

-

semiconductor assembly

-

CNC machining automation

-

robotic welding systems

-

packaging and palletizing

High-quality IMUs reduce:

-

tremor

-

vibration

-

path deviation

leading to millimeter-level precision.

3.3 Humanoid Robots and Legged Systems

Humanoids, quadrupeds, and exoskeletons rely on IMUs for:

-

balance control

-

gait synchronization

-

terrain estimation

-

fall detection

Examples:

-

biped robots walking on uneven surfaces

-

quadrupeds running dynamically

-

exoskeleton suits adapting to human movement