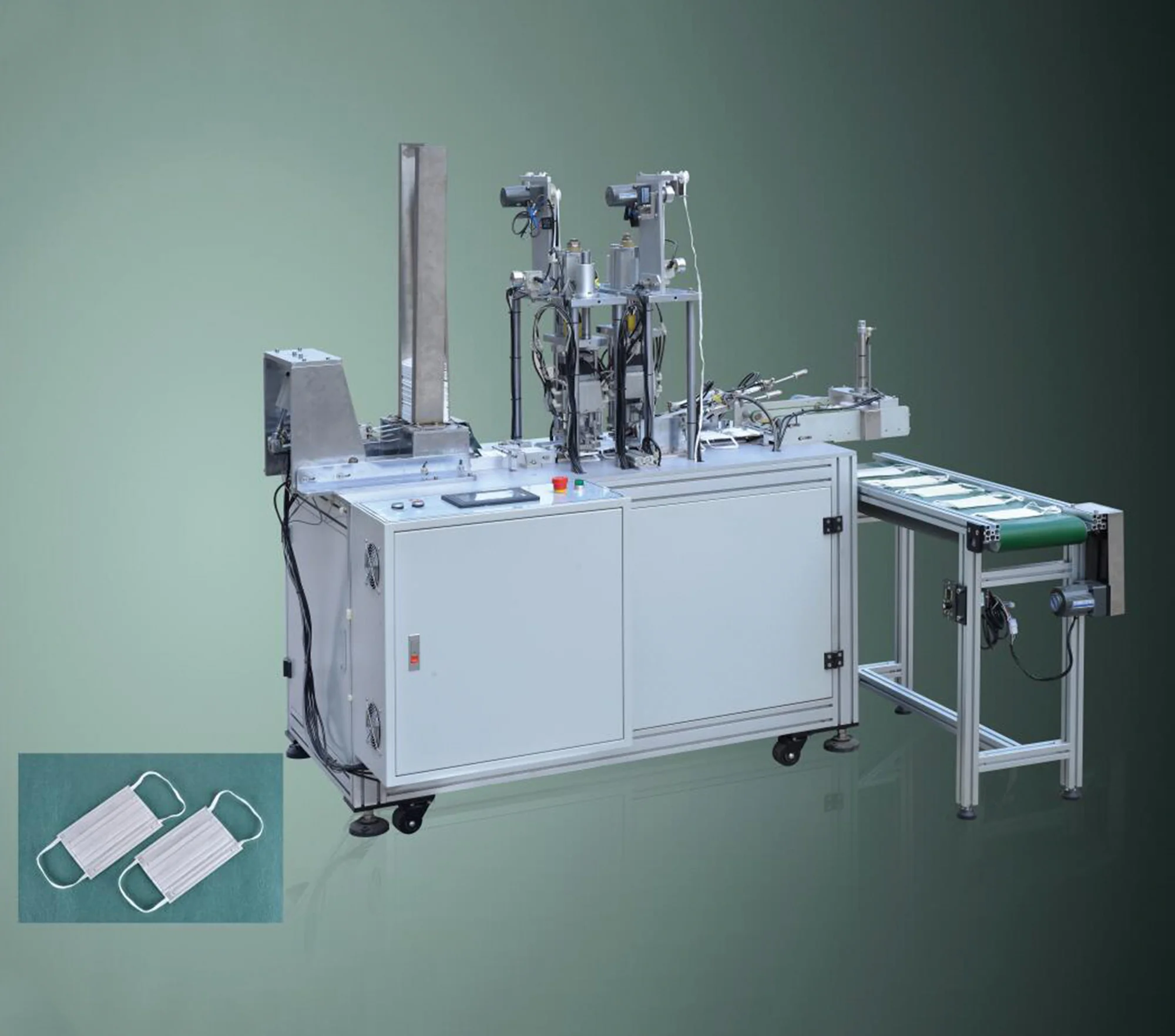

In the era of increased global demand for personal protective equipment (PPE), especially face masks, automated production technology has become indispensable for manufacturers seeking higher efficiency and quality. One critical piece of this technology ecosystem is the auto-feeding mask ear-loop outbound sealing machine, such as the BF-13-1 model — designed to streamline the final stages of mask production with precision and speed.

In this comprehensive guide, we’ll explore what the BF-13-1 machine does, why it matters in modern mask manufacturing, and how it fits into the broader product offerings of Broadfair Automation Equipment Co., Ltd. — a leading automation equipment provider based in China.

What Is the BF-13-1 Auto-feeding Mask Ear-loop Outbound Sealing Machine?

The BF-13-1 is an advanced automatic machine designed to feed masks, attach ear loops, and seal finished products at the outbound stage of mask production. These steps are critical in creating ready-to-use masks with consistent build quality and secure ear attachment — a key factor in wearer comfort and product performance.

Auto-feeding and sealing technology helps reduce manual labor, improve production consistency, and increase throughput — essential for factories producing flat masks, surgical masks, or other ear-loop-style protective masks in large volumes.

Key Features and Functional Benefits

While specifics for the BF-13-1 model are often provided directly by suppliers or manufacturers, typical features of high-performance auto-feeding and ear-loop sealing machines include:

Automatic Feeding System

The machine automatically feeds mask bodies toward the ear-loop station, continuously processing output from upstream equipment.

Precise Ear-loop Positioning and Welding

Using servo motors and ultrasonic welding or other sealing technologies, the ear loops are attached with high accuracy and strength, reducing defects and ensuring wearer comfort.

Integrated Outbound Sealing

After ear loops are attached, the machine moves finished masks to outbound packaging or stacking stations, enabling smooth workflow in continuous production.

High Throughput and Reliability

Designed for industrial environments, auto-feeding machines significantly outperform manual or semi-automatic alternatives in speed, stability, and repeatability.

About Broadfair Automation Equipment Co., Ltd.

Broadfair Automation Equipment Co., Ltd. is a Chinese high-tech enterprise specializing in R&D, production, and sales of automated mask production machines and non-woven converting equipment. Founded in 2006, the company operates a large facility equipped with CNC machining centers, precision tooling, and assembly infrastructure to support industrial-grade automation solutions.

Broadfair’s product lineup includes a variety of mask manufacturing machines such as flat mask machines, folding mask machines, and full automatic production lines — all designed to help PPE producers meet global market demands efficiently.

The company’s philosophy emphasizes quality first, technology innovation, and customer-centric service, with more than 45 technical patents and an ISO9001:2015 certification highlighting its commitment to engineering excellence.

How the BF-13-1 Fits into Automated Mask Production Lines

In a typical fully automated mask factory, mask production flows through multiple stages:

-

Raw Material Unwinding – Non-woven fabric is loaded and unwound.

-

Mask Body Forming – Layers are folded and shaped into mask bodies.

-

Ultrasonic Welding – Nose strips and layers are bonded.

-

Ear-loop Welding – Ear loops are attached with ultrasonic or heat sealing.

-

Outbound Sealing & Stacking – Finished masks are sealed, counted, and prepared for packaging.

The BF-13-1 machine is typically deployed at the final stage — automatically handling mask feeding, ear-loop sealing, and outbound delivery — enabling continuous, hands-free operation for end-to-end automated production.

Why Auto-feeding Ear-loop Machines Matter

With rising production standards and global PPE demand, relying on manual labor for ear-loop application and outbound handling has become a bottleneck for mask manufacturers. Automated machines offer clear advantages:

-

Improved Production Speed: Automated feeding and sealing dramatically increase production capacity per shift.

-

Consistent Quality: Each mask undergoes the same precise sealing process, reducing variation.

-

Labor Cost Savings: Fewer operators are needed to achieve higher output.

-

Reduced Downtime: Continuous automation minimizes production interruptions.

Brands like Broadfair help manufacturers achieve these benefits with robust machine design and solid engineering support.

Common Questions About the BF-13-1 Machine

Q1: What types of masks can the BF-13-1 machine handle?

A: Typically, auto-feeding sealing machines are designed for ear-loop masks, including flat masks and certain layers of protective masks. Compatibility depends on mask dimensions and ear-loop materials.

Q2: Is the machine easy to operate?

A: Yes — most modern sealing machines use PLC control systems and intuitive interfaces to streamline settings and monitoring.

Q3: What maintenance does it require?

A: Routine tasks include cleaning welding horns, checking tension on feeding systems, and calibrating sensors to maintain stable performance.

Q4: Can the BF-13-1 integrate with other production machines?

A: Yes — these machines are designed to connect seamlessly with upstream machinery to support a fully automated line.

Q5: What support does Broadfair offer?

A: Broadfair typically provides installation guidance, operator training, spare parts, and technical support to ensure long-term machine performance.

Conclusion

The BF-13-1 Auto-feeding Mask Ear-loop Outbound Sealing Machine represents an important component in modern mask production — bridging the gap between upstream forming systems and downstream packaging. By automating the tedious and precision-dependent steps of ear-loop sealing and outbound transfer, it boosts productivity, quality, and factory efficiency.

Backed by companies like Broadfair Automation Equipment Co., Ltd. — with deep experience in automated mask manufacturing equipment and global engineering support — manufacturers can achieve reliable, high-speed mask output that meets the rising demands of markets worldwide.

Folding Mask Machine Maintenance Tips for Long-Term Performance

www.broadfairmachine.com

Broadfair Automation Equipment Co., Ltd.