In modern industrial operations, efficiency, precision, and reliability are essential. One tool that has become indispensable in electrical, manufacturing, and logistics operations is the fixed cable tie machine. Unlike manual tie methods, fixed cable tie machines offer speed, consistency, and quality, helping businesses streamline processes and maintain high safety standards.

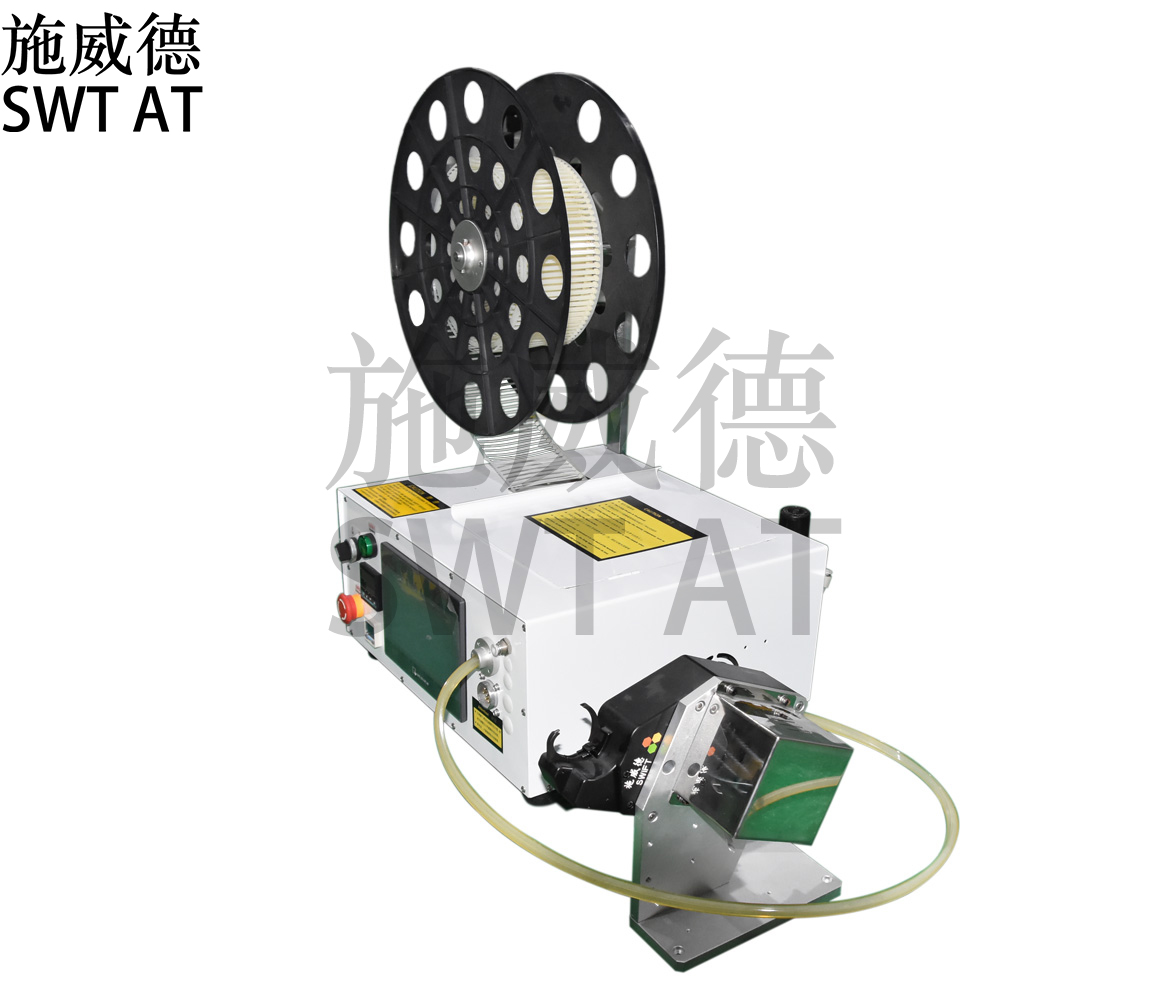

Swift Automation Technology is a global leader in the development and manufacturing of automatic cable tie tools and nylon cable ties. Their product range includes automatic nylon cable tie machines, handheld tools, and guns, along with a wide variety of complementary equipment and high-quality nylon cable ties. With years of industry expertise, Swift Automation provides solutions that optimize workflow and improve operational performance across multiple industrial sectors.

1. Enhanced Speed and Efficiency

One of the most significant advantages of fixed cable tie machines is time efficiency:

-

Rapid installation: Machines can tie multiple cables in a fraction of the time it takes manually.

-

Consistent performance: Ensures uniform tension and tightness for every tie, reducing rework.

-

Automation-ready: Can be integrated into assembly lines for continuous operations.

In high-volume industrial environments, Swift Automation’s fixed cable tie machines dramatically reduce labor costs and increase productivity.

2. Precision and Reliability

Fixed cable tie machines provide consistent and precise cable management, critical in complex industrial systems:

-

Uniform tensioning: Prevents over-tightening or under-tightening, which can damage cables or compromise stability.

-

Accurate placement: Ensures that cable bundles are neat, organized, and securely fastened.

-

Long-lasting results: Reduces the risk of loose cables, accidental disconnections, and safety hazards.

This precision is particularly important in electrical panels, automotive wiring, and large-scale manufacturing setups where reliability is paramount.

3. Safety Improvements

Cable management plays a direct role in workplace safety. Fixed cable tie machines help:

-

Minimize trip hazards: Properly bundled cables reduce clutter and accidents.

-

Reduce hand strain and injury: Automation removes the repetitive strain associated with manual tying.

-

Protect cables from damage: Prevents cuts or abrasions that can occur with manual tie methods.

Swift Automation’s machines are designed to meet industry safety standards, ensuring both operator safety and equipment integrity.

4. Cost Savings and ROI

Investing in a fixed cable tie machine may seem significant upfront, but the long-term benefits are clear:

-

Reduced labor costs: Faster operation means fewer man-hours required for cable management.

-

Lower material waste: Consistent tension reduces the risk of damaged ties.

-

Increased productivity: Streamlined operations allow employees to focus on other high-value tasks.

Swift Automation’s solutions are engineered for high-volume industrial use, delivering measurable cost savings and a quick return on investment.

5. Versatility and Scalability

Fixed cable tie machines can be adapted to a variety of industrial needs:

-

Different tie sizes and types: Handles various nylon tie widths and strengths.

-

Customizable settings: Adjust tension, feed speed, and tie placement according to project requirements.

-

Integration with automated systems: Perfect for large-scale manufacturing lines and logistics operations.

Swift Automation offers comprehensive support and customizable options, ensuring their machines meet the exact needs of different industries.

6. Improved Aesthetics and Organization

Beyond functionality, well-managed cables improve the overall appearance and organization of industrial setups:

-

Neat cable bundles: Makes maintenance and troubleshooting easier.

-

Professional presentation: Clean and organized installations reflect operational excellence.

-

Long-term system integrity: Proper cable management reduces strain on connections, prolonging equipment life.

With Swift Automation’s machines, businesses can achieve both efficiency and professionalism in cable management.

Conclusion

Fixed cable tie machines are an essential tool in industrial applications where speed, precision, safety, and reliability matter. From reducing labor costs and improving productivity to enhancing safety and system integrity, these machines offer a comprehensive solution for modern manufacturing and assembly needs.

Swift Automation Technology stands out as a global leader in automatic cable tie solutions, providing high-quality machines, tools, and nylon cable ties designed to optimize industrial operations. By adopting fixed cable tie machines from Swift Automation, businesses can enjoy faster workflows, better organization, and long-term operational efficiency.

www.sz-swift.com

Shenzhen Swift Automation Technology Co., Ltd.