In modern manufacturing, gear hobbing machines are essential for producing high-precision gears for industries ranging from automotive and motorcycles to pumps and industrial machinery. Selecting the right gear hobbing machine ensures accurate tooth profiles, high productivity, and long-term reliability, all of which are critical for a competitive production line.

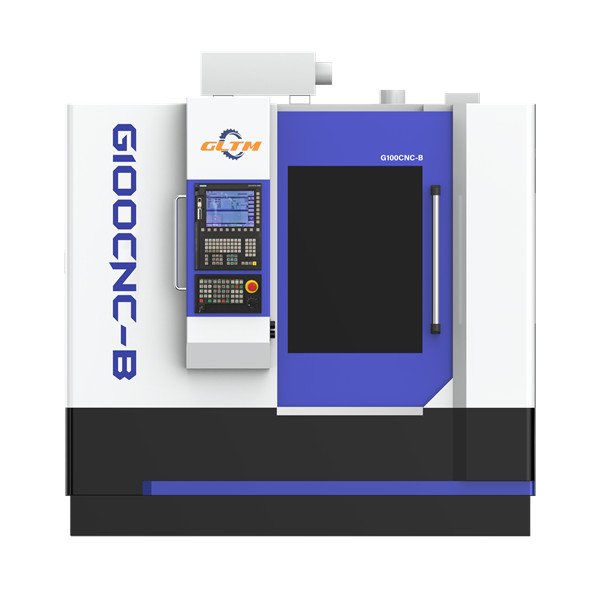

GLT Machinery (GLTM/GLT) is a leading Chinese manufacturer of CNC gear hobbing machines, specializing in high-speed, high-efficiency, and high-rigidity machines. With years of experience, GLT has successfully delivered customized gear cutting solutions for clients in automotive, motorcycles, reducers, synchronous pulleys, and pump industries. Their machines are engineered to meet precision, efficiency, and reliability requirements for modern manufacturing operations.

This article provides a comprehensive guide on how to choose the right gear hobbing machine for your production line, helping optimize performance and reduce production costs.

1. Understand Your Gear Production Requirements

Before selecting a gear hobbing machine, evaluate your production needs:

-

Gear Type and Size: Consider the types of gears you manufacture (e.g., spur gears, helical gears, worm gears) and their dimensions.

-

Material Type: Different materials such as steel, aluminum, or composites require specific machine rigidity and cutting speed.

-

Production Volume: High-volume production requires machines capable of continuous operation with minimal downtime.

GLT Machinery provides a range of machines that can be tailored to specific gear types, sizes, and production requirements, ensuring optimal manufacturing results.

2. Consider Machine Precision and Rigidity

Precision and rigidity are key to high-quality gear production:

-

Rigidity: A rigid machine frame reduces vibration and deflection, ensuring accurate tooth profiles.

-

Precision Control: CNC systems allow for precise cutting angles, depth, and gear profiles.

-

Repeatability: High repeatability ensures consistent gear quality across large production batches.

GLT’s high-rigidity CNC hobbing machines are designed to maintain precision under high-speed operation, making them ideal for automotive and industrial gear production.

3. Evaluate Cutting Speed and Efficiency

Modern production lines demand high-speed and high-efficiency gear cutting:

-

Spindle Speed and Feed Rate: Machines should offer adjustable spindle speeds and feed rates to match material type and gear size.

-

Automation Features: CNC control, automatic tool changers, and part handling systems reduce manual intervention and improve throughput.

-

Cooling and Lubrication: Efficient cooling systems extend tool life and maintain cutting accuracy.

GLT Machinery designs its machines with high-speed capabilities and optimized efficiency, reducing cycle times while maintaining gear quality.

4. Check Machine Versatility

A versatile gear hobbing machine can handle a wide range of gears and applications:

-

Different Gear Types: Capable of producing spur, helical, worm, and bevel gears.

-

Adjustable Hob Cutter Compatibility: Supports various hob cutters for different gear profiles and module sizes.

-

Customizable Fixtures: Allows easy setup for different workpieces and production batches.

GLT Machinery offers machines that adapt to multiple gear types and production needs, making them suitable for automotive, reducers, pumps, and pulley industries.

5. Consider After-Sales Support and Maintenance

Reliable after-sales support ensures long-term machine performance:

-

Technical Support: Access to machine setup, troubleshooting, and operator training.

-

Spare Parts Availability: Quick replacement of worn components reduces downtime.

-

Maintenance Guidance: Preventive maintenance instructions ensure consistent machine performance.

GLT Machinery provides comprehensive after-sales services, helping clients maintain productivity and minimize operational disruptions.

6. Benefits of Choosing GLT Gear Hobbing Machines

Selecting GLT Machinery offers several advantages:

-

High Precision and Reliability: Machines designed for accurate gear production and long-term durability.

-

Efficient Production: High-speed CNC machines increase throughput and reduce production costs.

-

Versatility: Supports various gear types and sizes, suitable for multiple industries.

-

Customized Solutions: GLT offers tailored gear cutting solutions to meet unique production requirements.

-

Global Expertise: Successfully supplied gear hobbing solutions to automotive, motorcycle, reducer, pulley, and pump industries worldwide.

By leveraging GLT Machinery’s experience and high-quality machines, manufacturers can achieve optimized gear production, superior product quality, and efficient operations.

Conclusion

Choosing the right gear hobbing machine requires careful consideration of gear type, material, precision, speed, versatility, and after-sales support. A well-selected machine improves production efficiency, reduces costs, and ensures consistent quality, which is vital for competitive industrial operations.

GLT Machinery (GLTM/GLT), with its focus on high-speed, high-efficiency, and high-rigidity CNC gear hobbing machines, provides tailored solutions for automotive, motorcycles, reducers, pulleys, and pump industries. By partnering with GLT, manufacturers can ensure their production lines are equipped with reliable, precise, and efficient gear cutting technology for long-term success.

www.gltmachinery.com

Wuxi General Machinery Co., Ltd. (GLTM / GLT)