As industrial automation continues to evolve, precision handling and positioning systems have become critical across sectors such as automotive, aerospace, mold manufacturing, and heavy machinery. Among the most advanced and versatile lifting solutions available today are five-axis crane gantries—integrated systems designed for high-precision, multi-directional material handling.

In this comprehensive guide, we’ll explore how five-axis crane gantries are used, the key benefits they offer, and best practices for maintaining them. We’ll also highlight the contributions of Zhiquan Electromechanical Equipment Co., Ltd., a professional manufacturer and supplier dedicated to the production and sale of high-performance five-axis crane gantry systems.

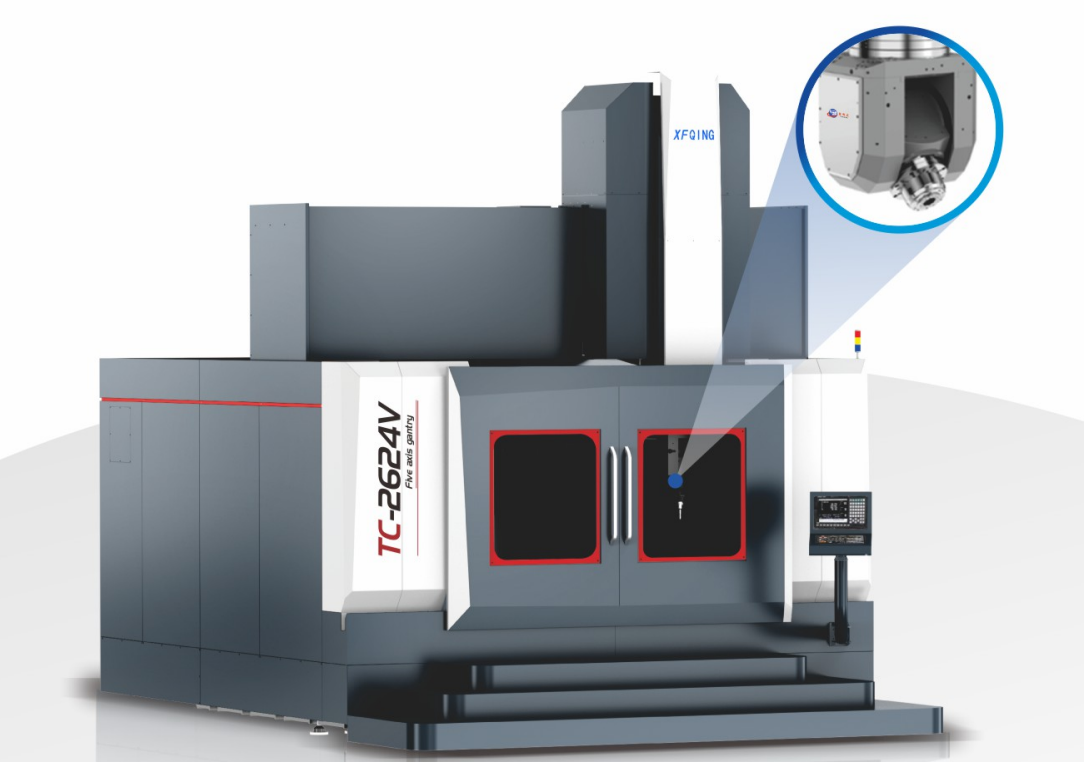

What Is a Five-Axis Crane Gantry?

A five-axis crane gantry is a sophisticated overhead gantry system capable of controlled movement across five degrees of freedom:

X-axis – horizontal movement along the length

Y-axis – lateral movement across the width

Z-axis – vertical lifting

A-axis – tilting or rotating movement (pitch)

B-axis – rotational or swiveling movement (yaw)

This enables the gantry to precisely lift, position, tilt, and rotate loads, making it ideal for complex, heavy, or awkwardly shaped components that require detailed orientation during processing, inspection, or assembly.

Applications Across Industries

Five-axis crane gantries are versatile systems used in various sectors:

Automotive Manufacturing: For precise positioning of large body parts or assemblies during production and quality control.

Aerospace: To handle sensitive, high-value components that require exact alignment and movement during machining or assembly.

Mold and Die Industry: For lifting and manipulating heavy dies or molds with minimal manual intervention.

Machinery and Equipment Assembly: To move and orient complex parts safely in multi-step manufacturing environments.

Railway and Shipbuilding: For large-scale structural component handling and positioning.

Key Features and Benefits

1. High Precision and Flexibility

With five degrees of movement, these gantries allow for complete spatial control, enabling users to manipulate components with exceptional accuracy.

2. Increased Productivity

By reducing the need for manual adjustment or repositioning, five-axis gantries streamline workflows, shorten cycle times, and reduce labor intensity.

3. Enhanced Safety

Automated lifting and multi-directional control minimize the risk of accidents, especially when handling heavy or irregularly shaped items.

4. Heavy Load Capacity

Engineered with high-strength steel and advanced drive systems, five-axis gantries can support significant weights while maintaining precision and balance.

5. Integration with CNC and Automation Systems

Many five-axis crane gantries can be integrated into automated production lines, working seamlessly with robotic arms, CNC machines, and digital control systems.

Zhiquan Electromechanical Equipment Co., Ltd.: Your Trusted Partner

Zhiquan Electromechanical Equipment Co., Ltd. is a professional enterprise specializing in the manufacture and sale of five-axis crane gantry systems. With a strong focus on technological innovation, quality control, and user-centered design, Zhiquan delivers solutions tailored to the evolving needs of modern industrial environments.

The company's five-axis gantries feature:

Advanced servo control technology for precise positioning

Robust mechanical structures for high-load performance

Customizable span and lifting height options

Smart operation interfaces with remote monitoring capabilities

Zhiquan’s gantries are widely used by industrial leaders seeking efficient, reliable, and intelligent lifting solutions for high-complexity operations.

Best Practices for Operation and Maintenance

To ensure long-term performance and safety, regular maintenance of five-axis crane gantries is essential. Here are key guidelines:

1. Routine Inspection

Check all axes for smooth movement and unusual noise

Inspect cables, pulleys, and drive belts for wear

Ensure limit switches and sensors are functioning properly

2. Lubrication and Cleaning

Lubricate moving parts as recommended by the manufacturer

Keep the rails, gear systems, and electrical contacts clean and free from dust and debris

3. Software and Control Systems

Regularly update control software and firmware

Calibrate axis movements and torque settings to maintain precision

4. Safety Systems Check

Test emergency stop buttons and overload protection features

Conduct periodic safety drills and staff training sessions

5. Professional Servicing

Partner with authorized technicians for periodic deep maintenance

Keep detailed service records to track performance trends and preempt potential issues

Conclusion

Five-axis crane gantries are revolutionizing material handling in precision industries, offering unmatched control, efficiency, and safety. With the ability to move and position loads in all spatial dimensions, they are indispensable in modern automated facilities.

Zhiquan Electromechanical Equipment Co., Ltd. continues to lead the field with its innovative and reliable gantry solutions, helping manufacturers worldwide achieve higher productivity, safer operations, and smarter workflows.

Whether you’re upgrading your current lifting system or building a new smart factory, investing in a high-quality five-axis crane gantry from a trusted provider like Zhiquan is a step toward precision-driven, future-ready industrial success.

Maintenance Tips for Five-Axis Gantry Cranes: Ensuring Longevity and Performance

www.szzhiquan.com

Suzhou Zhiquan Electromechanical Equipment Co., Ltd.